Kit Features

|

Design Philosophy:

Vacuum forming is an economical way to produce kits that would not be viable to manufacture via injection molding. Unfortunately, vacformed kits scare a lot of people. I created Titan Model Kits to be different from legacy vac kits by bringing the very latest manufacturing technology to the design and manufacture of the kits. I design each kit with the following goals in mind: 1. Be accurate. I start with accurate CAD models that attempt to faithfully replicate the subject. I use the best design data available. 2. Be accessible. Keep the number of vac parts to the bare minimum. Design the parts to be as easy to work with as possible. While you do need skill to build a Titan Model Kit, you shouldn't have to be an expert builder. |

|

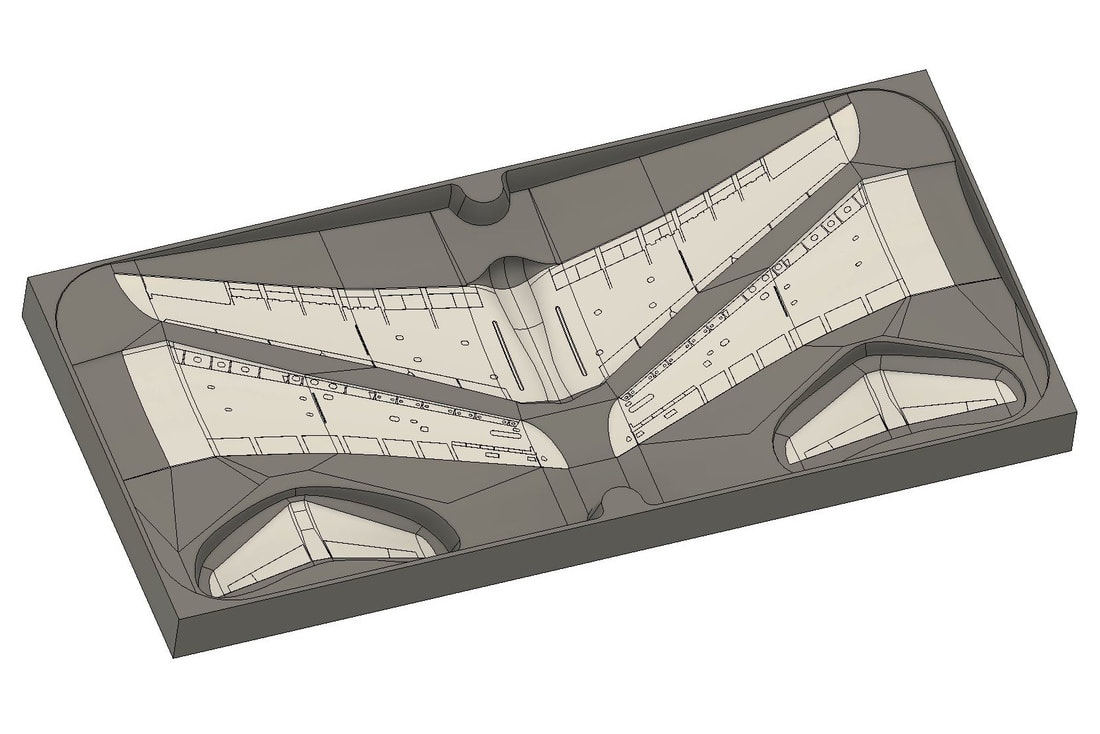

CNC Machined Cavity Molds:

Titan Model Kits cavity molds are designed with features to improve part shape, improve kit design, and make working with the resulting parts as easy as possible. CNC machining means that resulting parts are symmetrical and properly shaped. It means that fine panel lines and details are molded right in. |

|

Sturdy Construction Materials:

If you've encountered vacformed kits in the past you may have encountered thin plastic that was flimsy and difficult to build. Titan Model Kits uses thick .080" (2mm) and .100" (2.6mm) (depending on part size and geometry) high-impact-polystyrene (HIPS) plastic that is easy to work with and creates a sturdy model. Fuselage halves are reinforced with styrene angle strips for additional rigidity. |

|

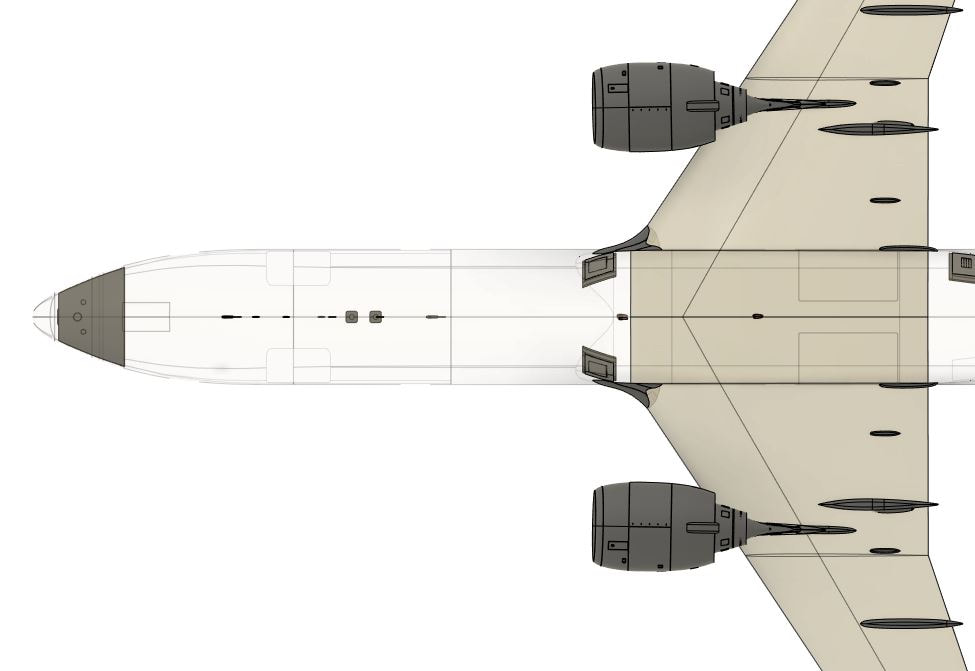

Wing Carry-Through:

Titan Model Kits wings and horizontal tails are designed to carry through the fuselage and meet in the very center of the kit. This means that dihedral is engineered right in the the part so there is no adjusting to get the wing angles to match and the resulting construction is extremely strong. |

|

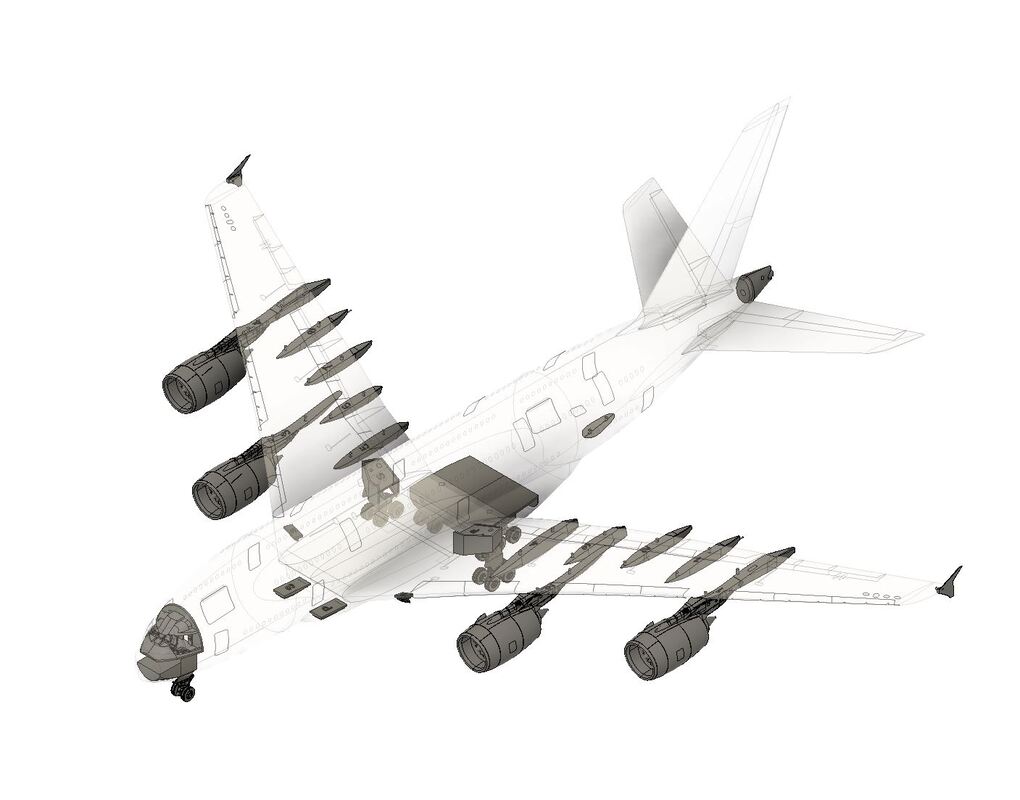

No Small Vacformed Parts:

Gone are the days of meticulously cutting out dozens of tiny, poorly formed vacformed parts to make rudimentary wheels and details. All of Titan Model Kits detail parts are 3D-printed in ultra-high resolution resin. Vac parts are kept to the absolute minimum--typically fuselage halves, wing halves, and horizontal stab halves. |

|

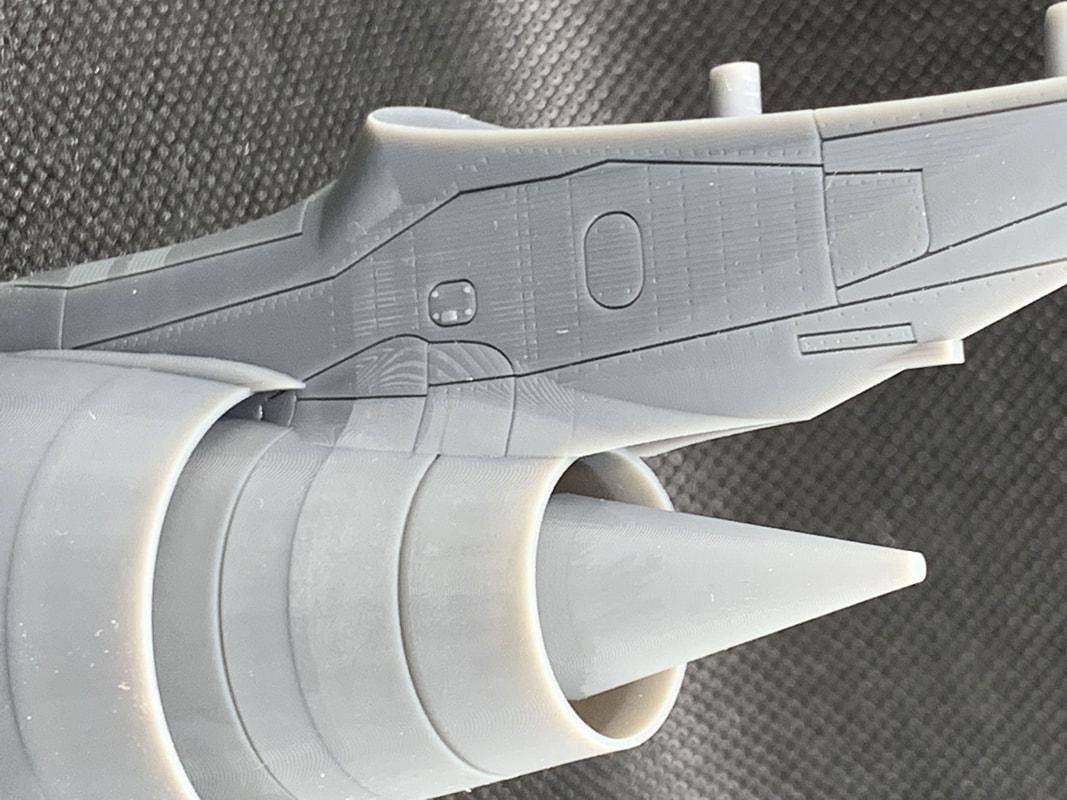

Ultra-detailed 3D Printed Parts:

Vacformed kits of the past often came with chunky cast metal or primitive short-run injection molded detail parts. Titan Model Kits use only cutting-edge, ultra-high-resolution UV-cured resin printing technology to create parts that often surpass the detail of injection molded kits and rival the detail of cast resin parts. With a few exceptions, Titan Model Kits' 3D-printed parts are all delivered with the support structures removed. |

|

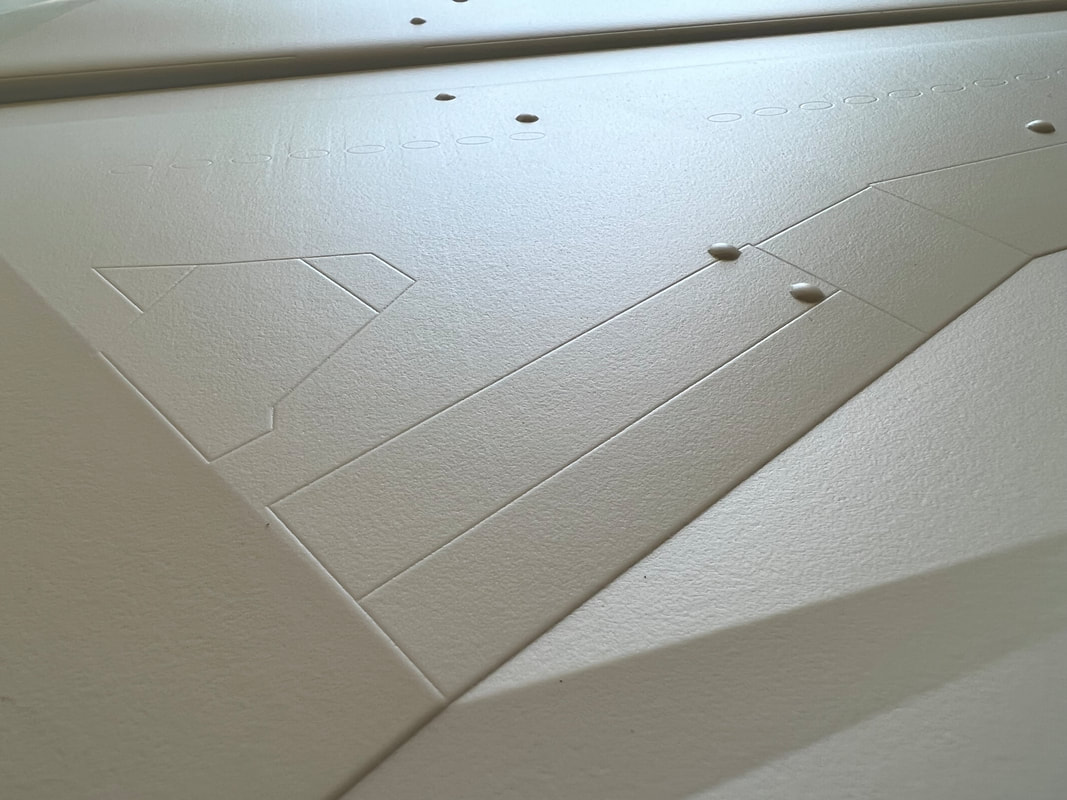

Positive Positioning of Resin Parts:

Mold vent holes double as positioning holes for mounting engines and flap track fairings. No more measuring or guessing where components go. Additionally, vac parts are designed with surface markings designating areas to cut and remove material in order to fit resin parts like NACA vents and wheel wells. Just cut out the designated areas and pop in the resin parts. Beginning with the release of the A380 kit, wheel wells are designed with a lip that fits perfectly into the wheel well cutouts to positively position the wheel well and provide a clean seam between the vac and resin part. |

|

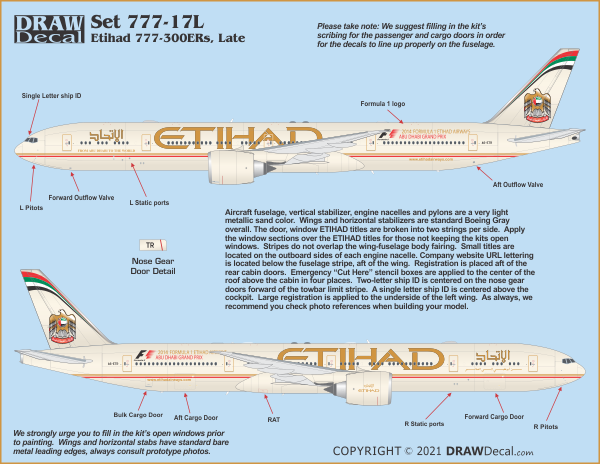

Decals:

In order to give you lots of options for your build, Titan Model Kits has partnered with DRAWDecal.com to provide decals. Titan Model Kits stocks some of the most common liveries for each kit and additional livery options are often available by purchasing directly from DRAWDecal.com. During checkout, you can select the decal set that you'd like or you can opt for no decals and purchase them later from DRAWDecal.com DRAWDecal uses 'Digital Silk' printing technology with a continuous carrier film over the entire sheet. Follow their application instructions to apply. |